|

About Us

Contact

S.S.PCB

D.S.PCB

MULTI PCB

HDI PCB

Aluminum Based-PCB

FULL FLEX PCB¡¡

Major Client

Technics Flow Line

Major Equipment

100 top world PCB makers

Certificate

News

Trademark and its Brand

PCB Quote

Service1£º Overseas Overseas

Service2£º Overseas Overseas

Service3£º Domestic Domestic ¡¡ |

|

Welcome to huading-group

Double Side board Main Application:

Consumer¡¢Telecom¡¢Industrial¡¢Aero Industry

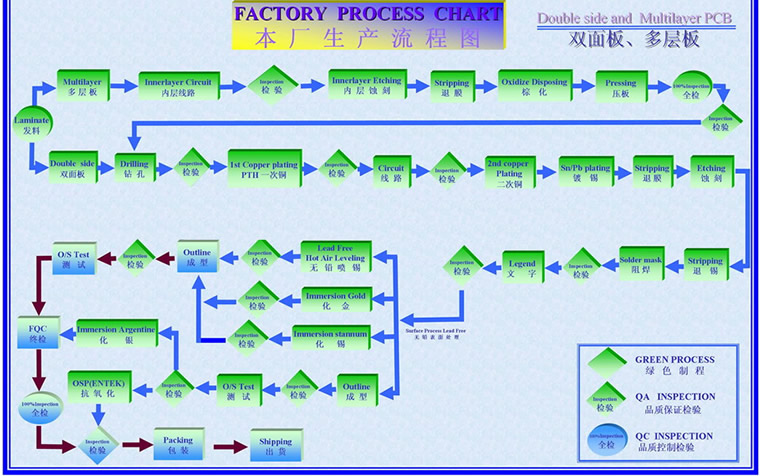

Technical Flow Chart

¡¡

Plant

Technological Advantages

|

Processing capabilities in many fields:

¡ñ Double-sided ~ High Multi-layer PCB (max. 40-layer)

¡ñ HDI (2+X+2 Build UP)¡¡

¡ñ HDI thin PCB (0.25mm for 4-layer, 0.40mm for

6-layer)

¡ñ Big size, Back plane PCB (Panel size at

24¡±x36¡±, Thickness of 4.5mm or more)

¡ñ Special-purpose PCB (Heavy copper(6oz) PCB, /

Buried resistance PCB)

¡ñ Via hole copper plating

¡ñ Thick gold

¡ñ Uneven gold finger |

|

Workstation |

Content |

|

Inner layer imaging |

Both wet and dry film, auto-exposure

machines from Japan, horizontal etching

lines from Germany, enhancing the capability

to produce min. 40¦Ìm -thick CCL and min.

width/gap 40¦Ìm/40¦Ìm. |

|

Laminating |

Leading integrated hot and cold laminating

machines from Germany, able to process up to

40-layer PCB. Pressing the min. thickness of

0.20mm, the max. thickness of 5mm or more,

with excellent thickness uniformity. |

|

Mechanical drilling |

HITACHI CNC drilling machines to ensure the

min. hole diameter of 0.10mm with high

precision. |

|

Laser drilling |

HITACHI CNC laser drilling machines to

ensure the min. hole diameter 0.075mm,

drilling speed 20,000 holes / min or more,

high-density interconnect board producing. |

|

Copper plating |

Pulse plating / Continuous vertical panel

plating, special tools for 40¦Ìm -thick CCL

,to achieve Aspect Ratio with 20:1 and good

copper distribution COV¡Ü6%. |

|

Copper electroplating micro via filling |

Applying selected special chemical additives

,optimized ?electroplating process parameter

,together with the appropriate

electroplating equipment, to ?fulfill the

high-end customer's requirement on high

quality of high board thickness to via

diameter ratio blind via and through via

filling capability, to ensure the

reliability of the HDI PCB. |

|

Solder mask print |

E-spray technology, able to print over 0.1mm

thin PCB, and max.12 oz heavy copper with

solder mask thickness¡Ý5um on trace edge. |

|

Electrical Test |

Four-terminal tester, the min. test pad

diameter at 0.1mm, min. test resistance at

10 milliohms to ensure quality and

reliability of the HDI PCB. |

|

Special carbon printing |

Special configuration of the carbon &

dielectric paste print line, life test up to

18 million cycles to ensure product

reliabilities. |

|

|

¡¡

|

|

|