![]()

×

单击图片或按ESC键关闭

document.head.appendChild(style);

HD-MC04 Aluminum-based PCB Technical Data sheet

Test base :

HD-MC04 Aluminum-based PCB

Thickness of copper:35um

Dielectric layer : 120um-130um

Cu base: 1.6mm

The result of the test:

|

No |

Test item |

U. |

Assay |

|

1 |

Peel Strength |

A |

N/mm |

1.5 |

|

After thermal stress(260℃) |

N/mm |

1.3 |

|

2 |

Blister test After Thermal stress |

/ |

(288℃,2min)

No Delamination,No blister |

|

3 |

Thermal resistance |

℃/W |

0.45 |

|

4 |

Thermal-conductive Factor |

W/m·k |

2.2 |

|

5 |

Flammability(A) |

/ |

FV-0 |

|

6 |

Surface Resistivity |

A |

MΩ

|

3.68×107 |

|

Constant humidity treatment(25℃~65℃,

RH:90%~98%,20 circulate) |

3.39×106 |

|

7 |

Volume Resistivity |

A |

MΩ

|

4.2×108 |

|

Constant humidity treatment(25℃~65℃,

RH:90%~98%,20 circulate) |

3.17×107 |

|

8 |

Dielectric Breakdown AC(leakage 5mA) |

KV |

6 |

|

9 |

Dielectric constant(1MHZ)(40℃,93%,96h) |

/ |

4.24 |

|

10 |

Dielectric dissipation factor

(1MHZ)(40℃,93%,96h) |

/ |

0.03 |

|

11 |

CTI |

V |

600 |

|

12 |

Operating Breakdown (AC) |

V |

500 |

|

13 |

Glass transition |

℃ |

125 |

|

14 |

Thickness |

um |

120 |

Method Description

1- Optical 2- Internal TO-220 test RD2018 3- Calculation from ASTM 5470

4-Extended ASTM 5470 5-ASTM D149 6-ASTM D150 7-Internal MDSC test RD2014

8-UL 746E 9-ASTM D2861 10- CPCA 4105-2010

Note: For applications with an expected voltage over 480 Volts AC,

HUADING recommends a dielectric thickness greater than 0.003”(76um)

Note: Maximum test voltage is a function of material and circuit

design.Typical proof test not represent the maximum.

Note: Circuit design is the most important consideration for determining

safety agency compliance.

HD-MC06 Aluminum-based PCB Technical Data sheet

Test base :

HD-MC06 Aluminum-based PCB

Thickness of the copper:35um

Dielectric layer:120um-130um

Thickness of the aluminum-base: 1.6mm

The result of the test:

|

No |

Test item |

U. |

Assay |

|

1 |

Peel strength |

A |

N/mm |

1.4 |

|

After thermal stress(260℃) |

N/mm |

1.2 |

|

2 |

Blister test After Thermal stress |

/ |

(300℃,2min)

No Delamination, No Blister |

|

3 |

Thermal resistance |

℃/W |

0.4 |

|

4 |

Thermal-conductive Factor |

W/m·k |

2.5 |

|

5 |

Flammability(A) |

/ |

FV-0 |

|

6 |

Surface Resistivity |

A |

MΩ

|

3.5×107 |

|

Constant humidity treatment(25℃~65℃,

RH:90%~98%,20

circulate) |

3.38×106 |

|

7 |

Volume Resistivity |

A |

MΩ

|

4.3×108 |

|

Constant humidity treatment(25℃~65℃,

RH:90%~98%,20

circulate) |

3.2×107 |

|

8 |

Dielectric Breakdown AC(leakage

5mA) |

KV |

6 |

|

9 |

Dielectric constant (1MHZ)(40℃,93%,96h) |

/ |

4.1 |

|

10 |

Dielectric dissipation factor(1MHZ)(40℃,93%,96h) |

/ |

0.031 |

|

11 |

CTI |

V |

600 |

|

12 |

Operating Breakdown (AC) |

V |

500 |

|

13 |

Glass transition |

℃ |

130 |

|

14 |

Thickness |

Um |

120 |

Method Description

1- Optical 2- Internal TO-220 test RD2018 3- Calculation from ASTM 5470

4-Extended ASTM 5470 5-ASTM D149 6-ASTM D150 7-Internal MDSC test RD2014

8-UL 746E 9-ASTM D2861 10- CPCA 4105-2010

Note: For applications with an expected voltage over 480 Volts

AC,HUADING recommends a dielectric thickness greater than 0.003”(76um)

Note: Maximum test voltage is a function of material and circuit

design.Typical proof test not represent the maximum.

Note: Circuit design is the most important consideration for determining

safety agency compliance.

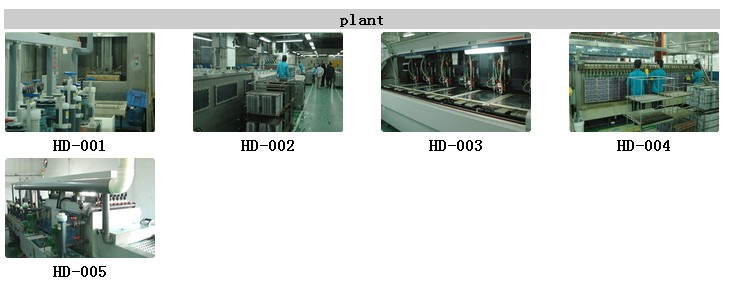

Plant