|

Welcome to huading-group

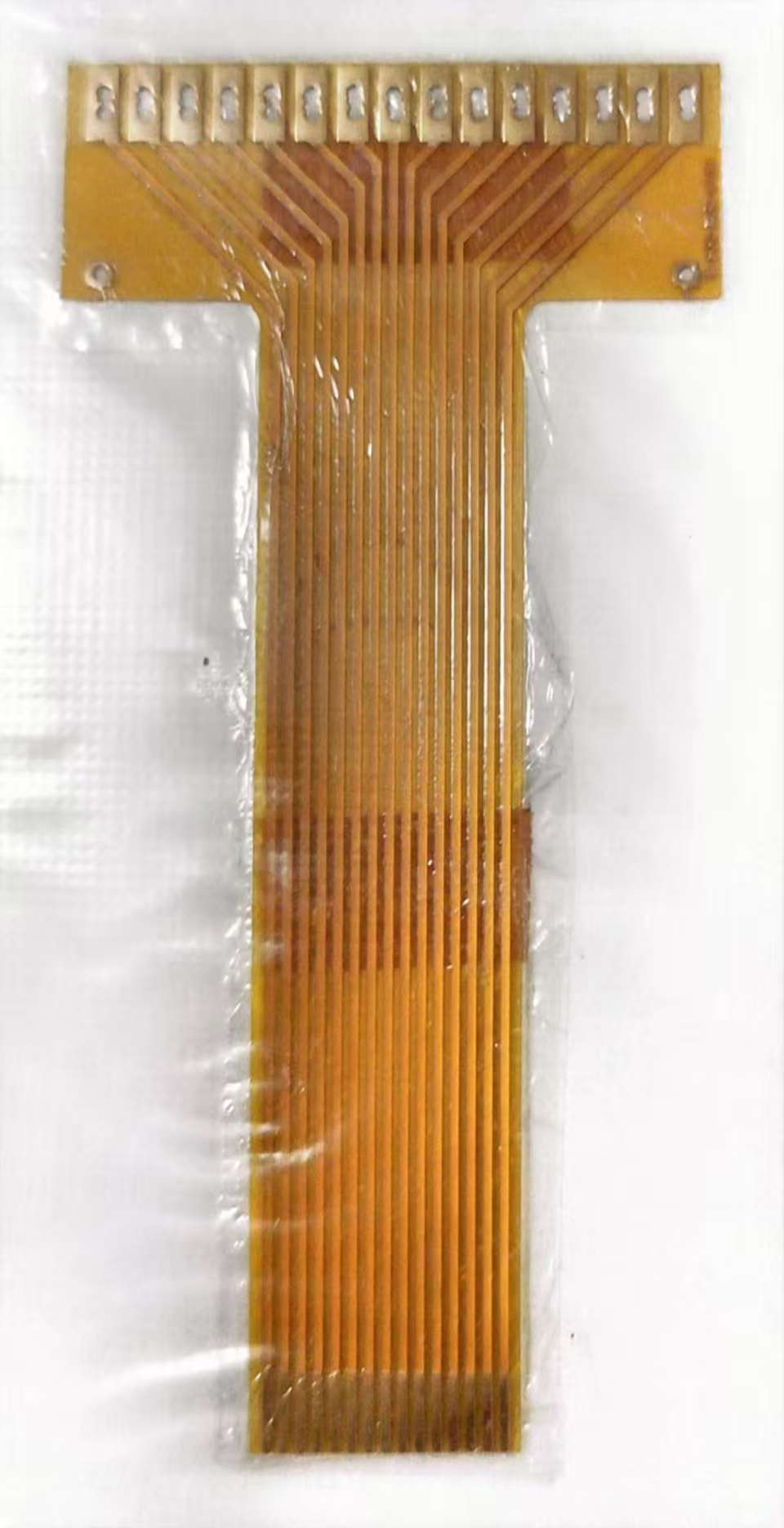

柔性板技术详解 | Flexible PCB

什么是柔性板?

柔性板(FPC)是以柔性绝缘材料为基材,可弯折、可折叠的印制电路板,广泛用于空间受限和动态应用场景。

柔性板的特点

灵活弯曲性

具有优异的柔韧性,可在三维空间内任意弯曲折叠,适应复杂结构设计。

轻量超薄

厚度可做到0.1mm以下,重量极轻,为紧凑型电子产品提供理想解决方案。

动态可靠性

经特殊设计可承受数百万次弯折而不失效,适合动态连接应用场景。

集成化设计

替代传统线缆和连接器,简化系统结构,提升连接可靠性和稳定性。

柔性板主要材料

聚酰亚胺(PI)

覆铜箔(RA)

覆铜箔(ED Copper)

高可靠性胶系

无胶基材

结构类型

✓ 柔性板材料体系均可提供 UL 认证支持。

柔性板应用场景

消费电子

医疗设备

汽车电子

工业设备

摄像与显示模组

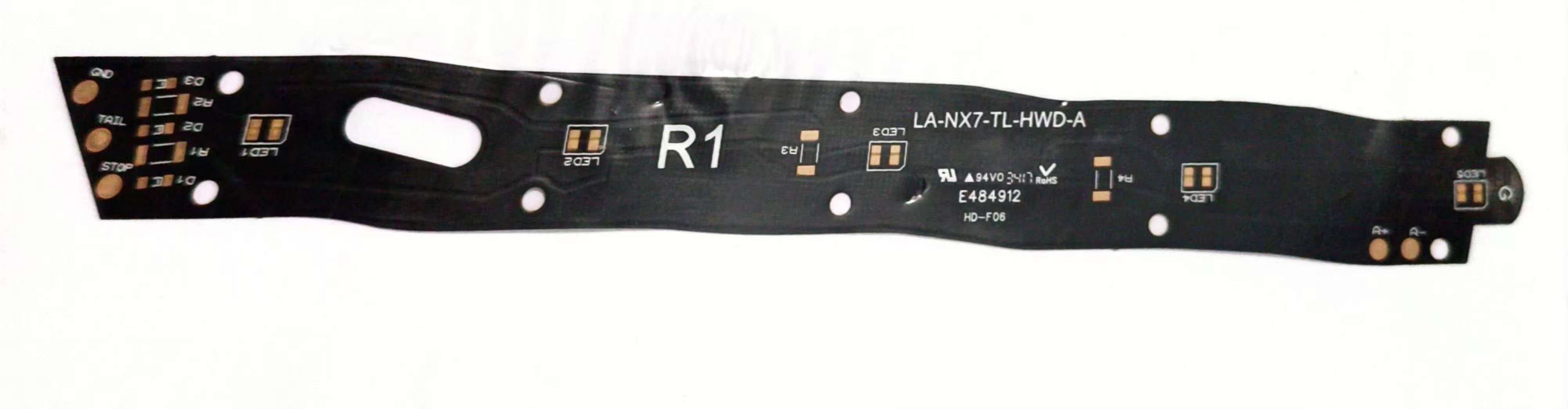

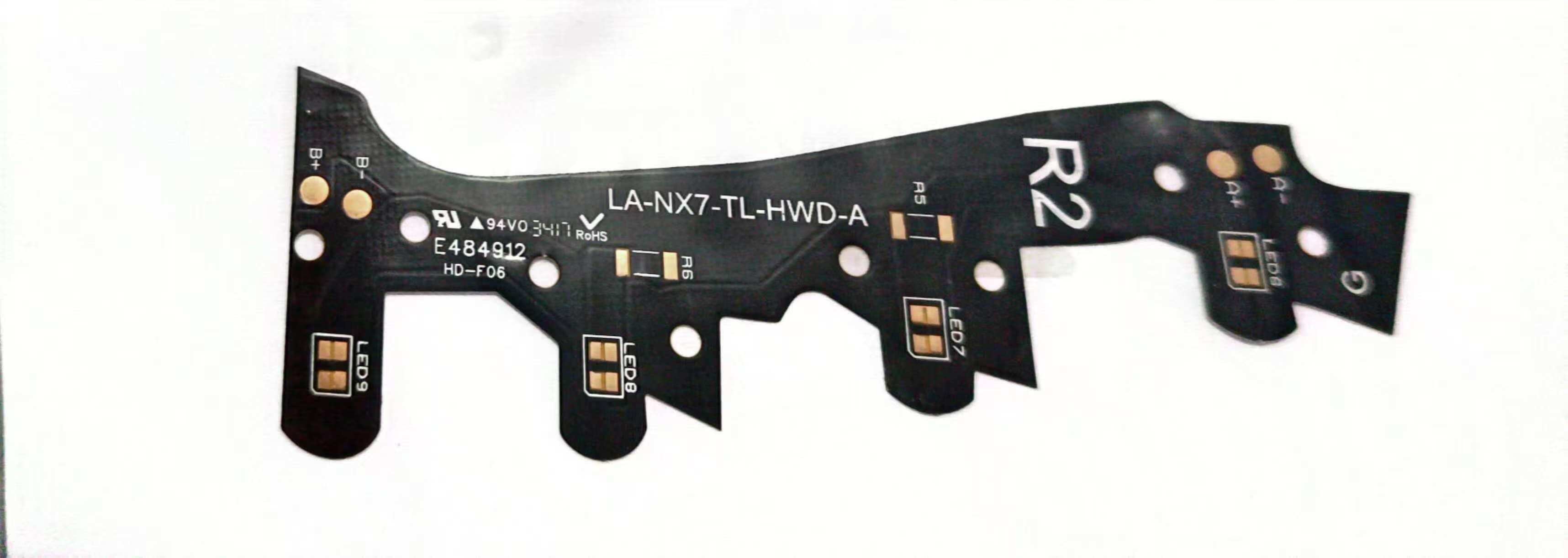

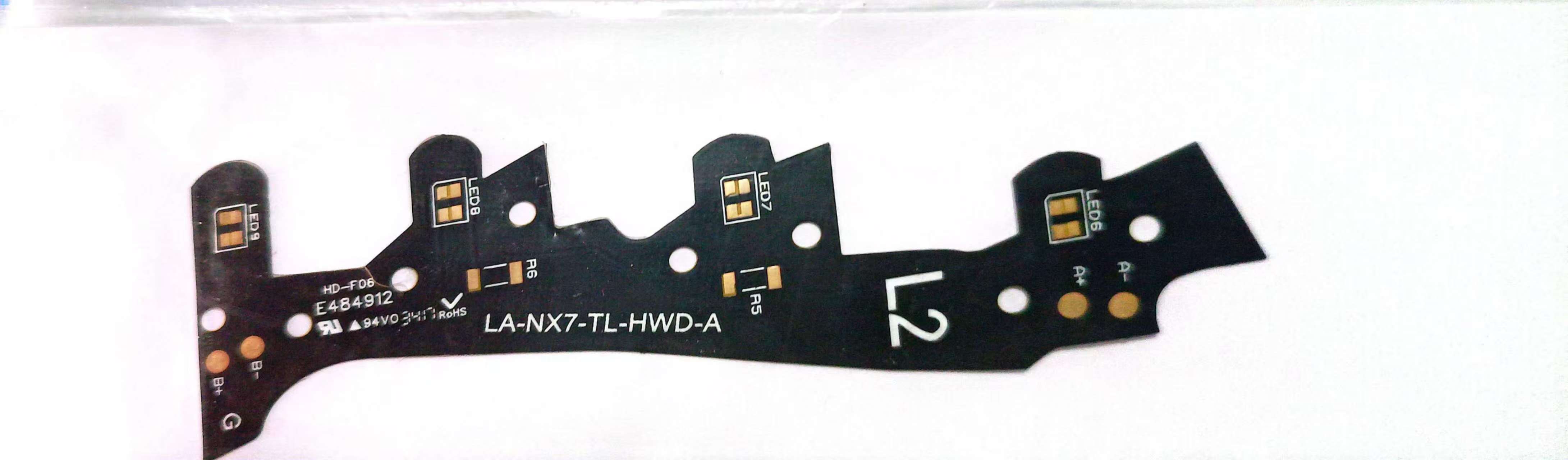

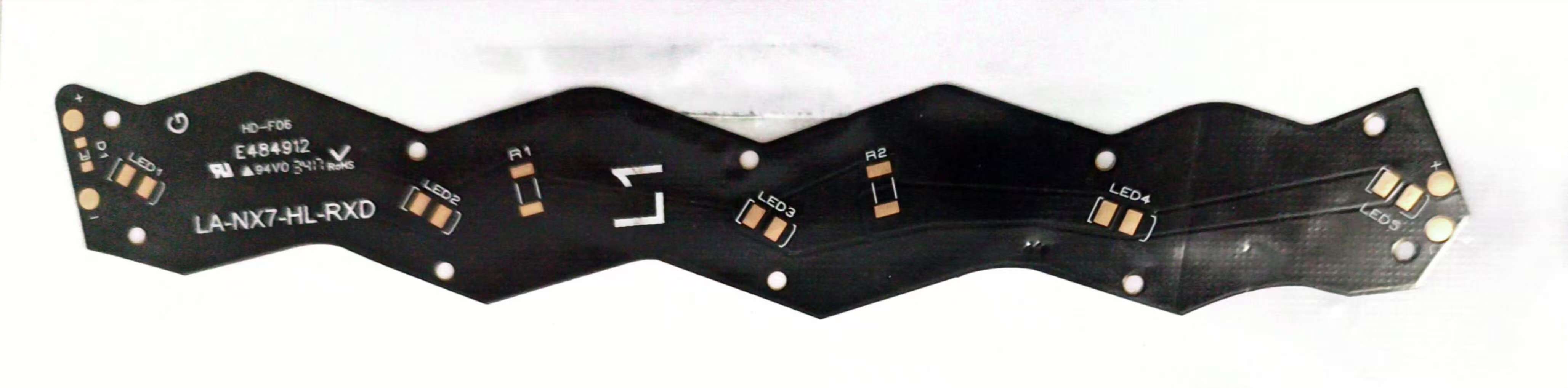

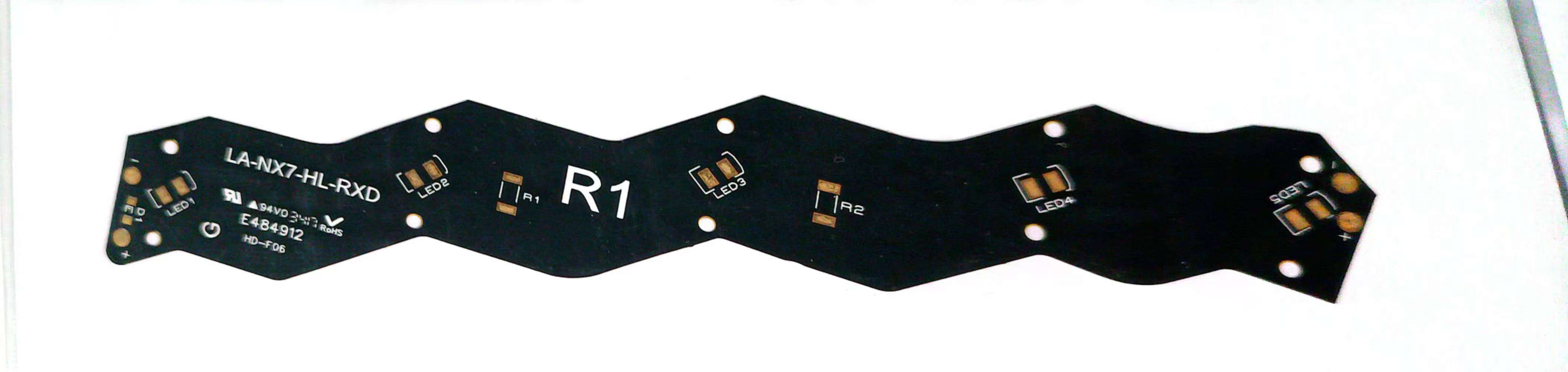

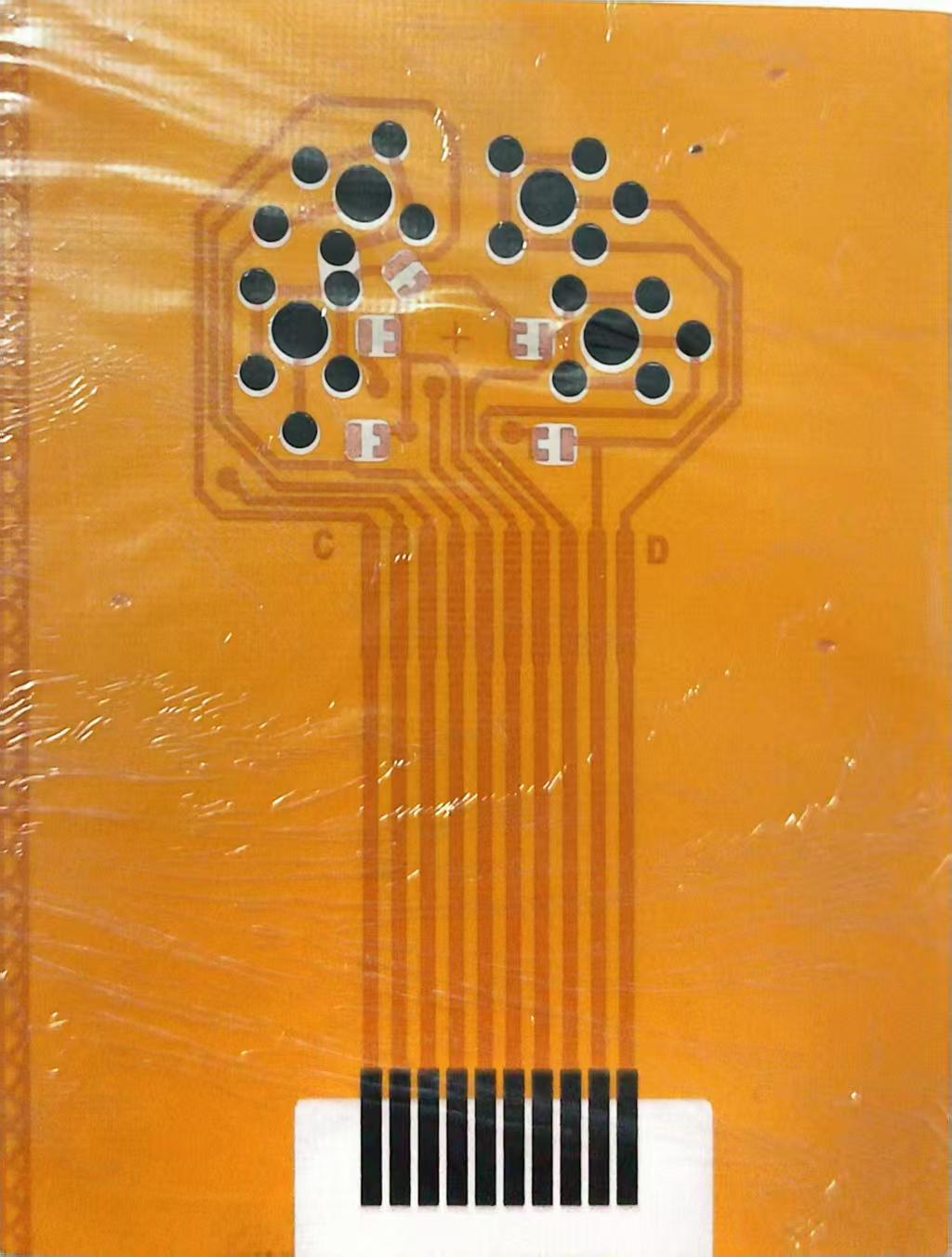

full flex pcb effect diagram

![]()

×

单击图片或按ESC键关闭

![]()

×

单击图片或按ESC键关闭

Technical Specification

Scope of products :

Single-side FPC, double-side FPC, multilayer FPC, aluminum substrate,

copper substrate, single-side hollowed-out FPC and double-side

hollowed-out FPC

Thinnest substrate :

Copper foil/PI film: 18/12.5 um 12/18um

Smallest wire width and distance :

0.05mm/0.05mm (2mil/2mil)

Smallest aperture :

0.25mm (10mil)

Resistance to flexural cracking :

> 150,000 cycles

Etching tolerance :

± 0.5 mil

Tolerance for exposure and alignment :

± 0.05mm (2mil)

Tolerance for projection punching :

± 0.025mm (1mil)

Tolerance for PI film alignment :

< 0.10mm (4mil)

Tolerance for reinforcing and take alignment : < 0.1mm (4mil)

Maximum processing area :

25cm × 60cm for double side; 25 cm × 10000cm for single side; 25cm ×

60cm for multilayer

Forming tolerance :

± 0.05mm

Mode of surface treatment :

Electroplated guiding :

1-5u "

Chemical gilding :

1-3u "

Pure electroplating tine :

4-20u "

Chemical tin :

1-5u "

Antioxidatio n

(OSP) 6-13u"

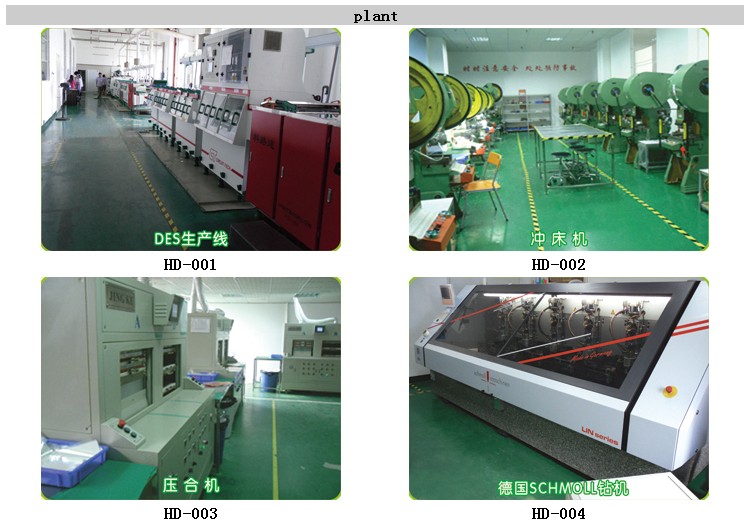

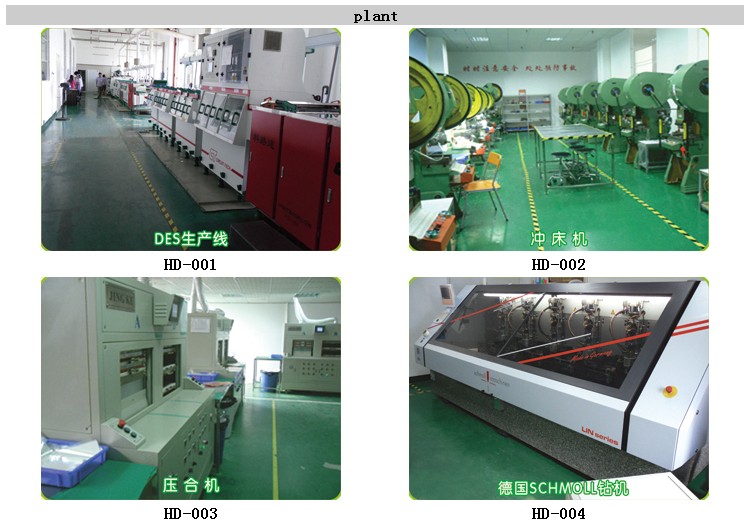

Plant

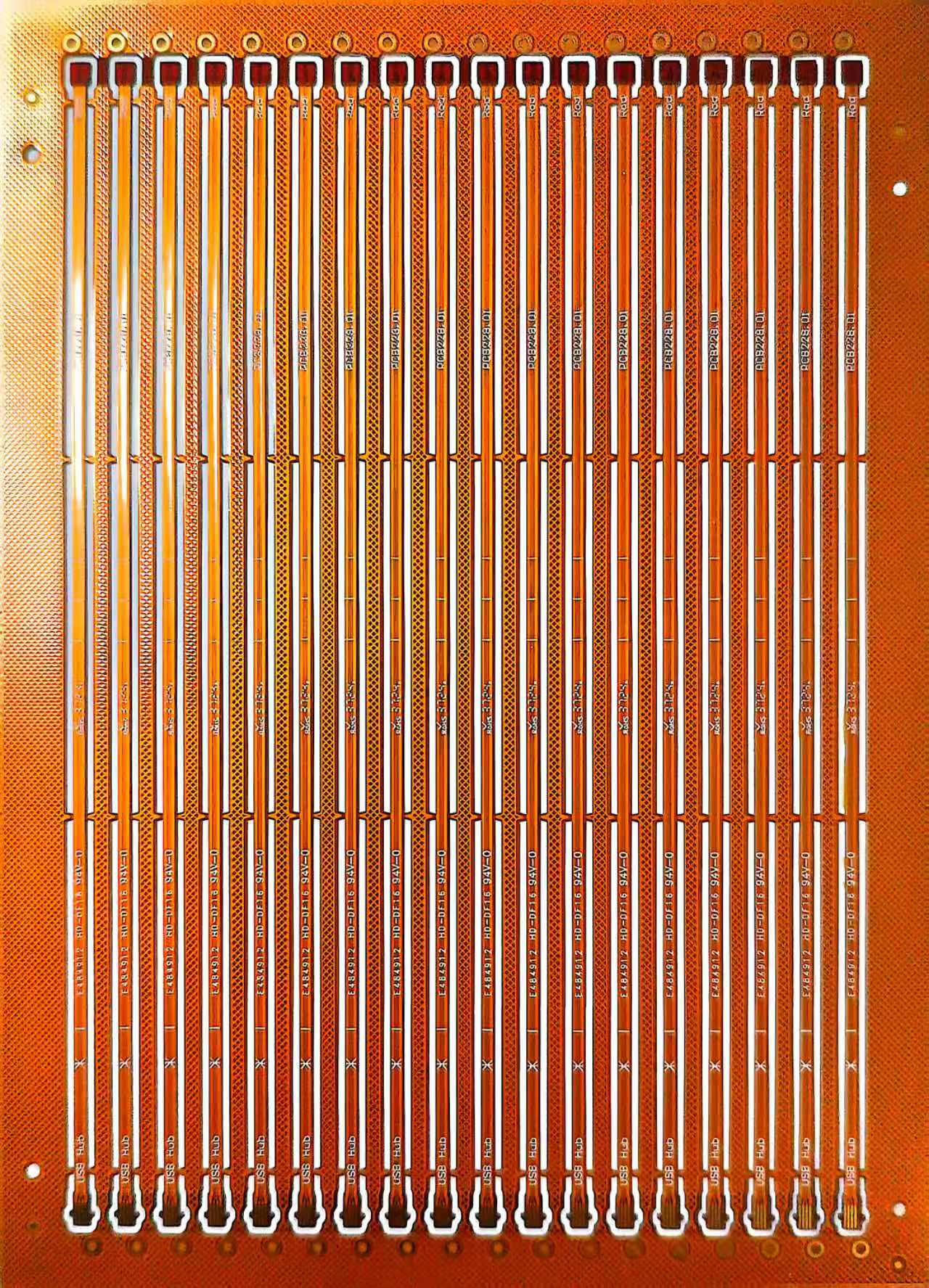

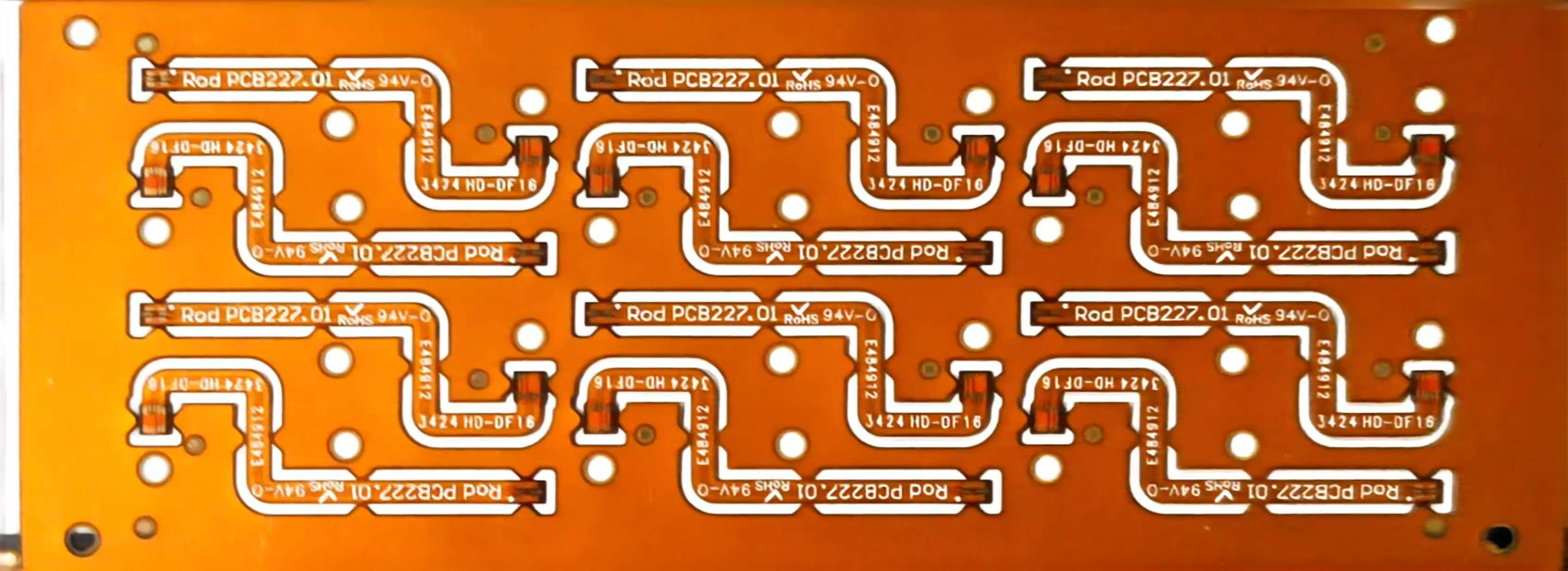

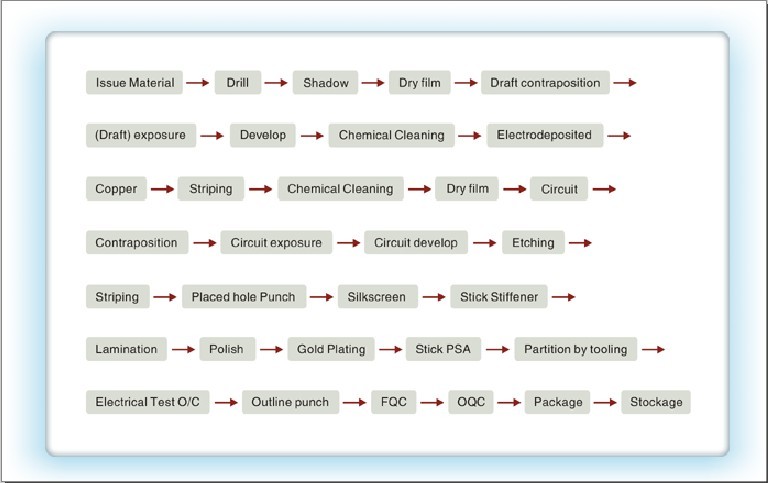

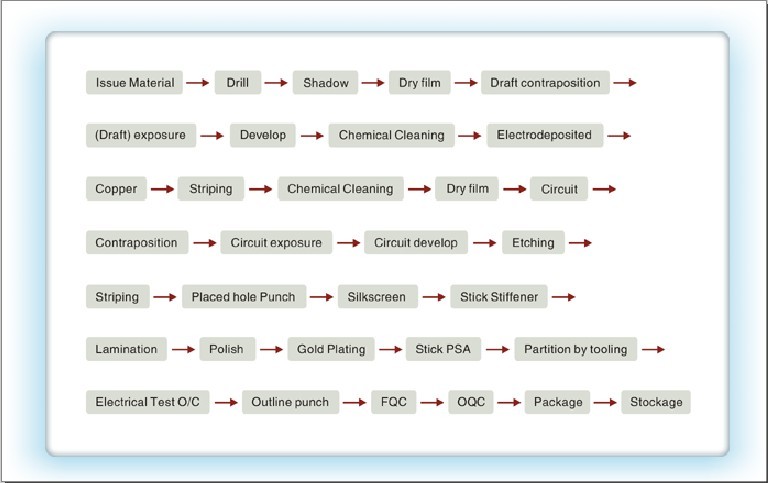

The production process : full flex pcb

|